In the fast-paced world of construction, efficiency and safety play vital roles in a project’s success. One crucial element that significantly contributes to these factors is proper equipment maintenance. Keep reading to learn why equipment maintenance matters in construction, including its importance in enhancing productivity and minimizing potential risks.

Increased Efficiency and Productivity

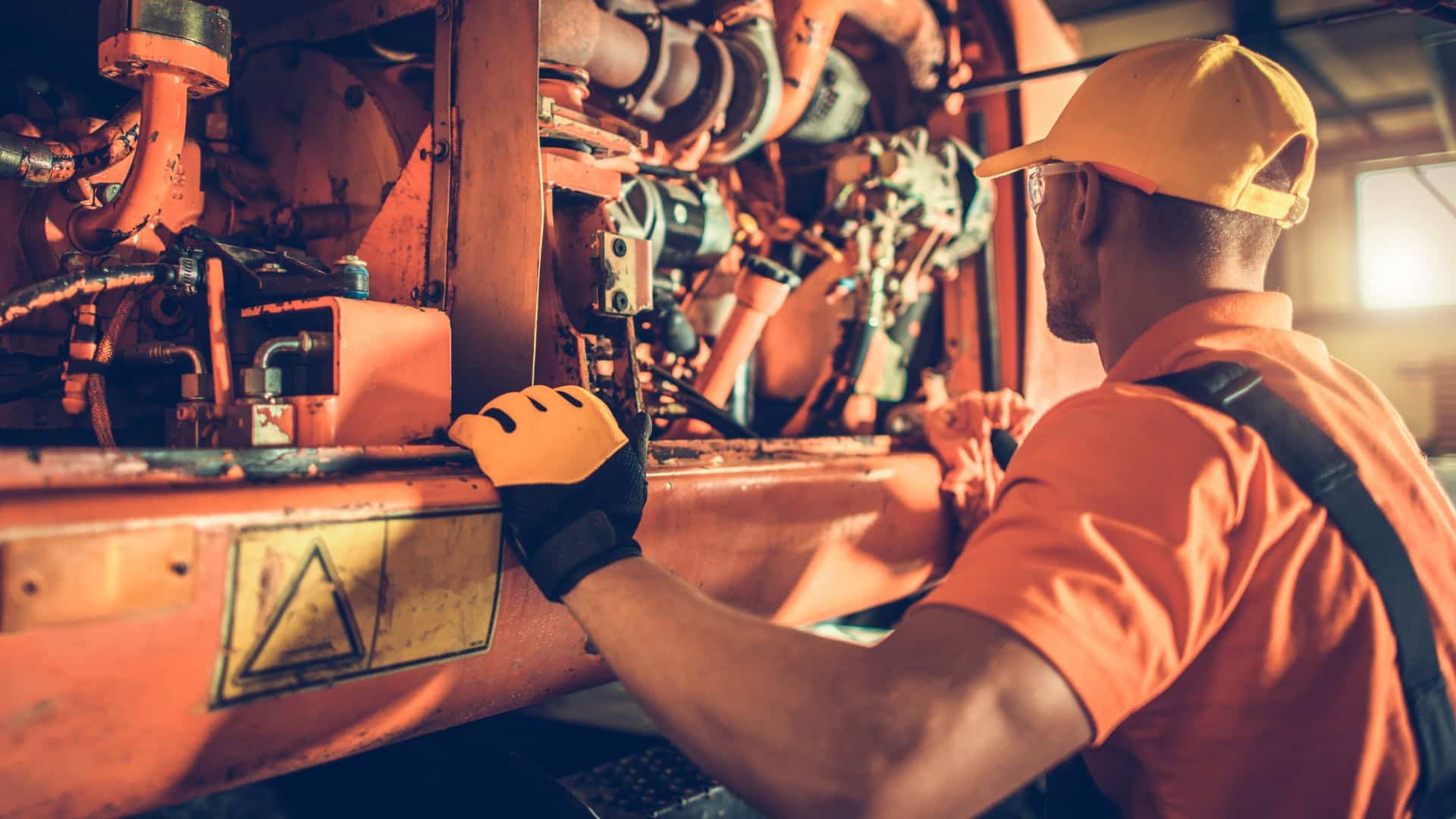

Well-maintained equipment is essential for increasing efficiency and productivity in a jobsite. Regular maintenance ensures that machinery operates at optimal capacity, reducing the likelihood of breakdowns and downtime. Maintenance also helps diagnose issues early on, saving valuable time and resources for repairs.

Extended Lifespan of Equipment

Investing in regular equipment maintenance not only ensures the proper functioning of machinery but also significantly extends its lifespan. For example, one of the top auger drilling mistakes is ignoring regular maintenance and allowing the tool to deteriorate at a faster rate. Proactive maintenance can save a construction company significant money in the long run, as longer-living pieces of equipment reduce the need for frequent, costly replacements.

Enhanced Safety and Reduced Risk

Unquestionably, construction sites can be hazardous environments, and the equipment operators and workers often face various risks during work. Well-maintained machinery reduces these risks and ensures a safer worksite. It also minimizes the chances of equipment-related accidents, leading to a safer environment and fewer potential liabilities for the company.

Compliance With Regulations

In many countries, construction companies must adhere to strict equipment maintenance regulations. These may include regular inspections and upkeep to ensure the machinery, such as bulldozers, excavators, and more, meets industry standards for safety and functionality. Proper maintenance and documentation help companies stay compliant and avoid costly fines and penalties.

Environmental Impact and Savings

Regular equipment maintenance can also have positive environmental effects. Properly maintained machinery consumes less fuel and energy, leading to lower emissions and a smaller carbon footprint. This not only benefits the environment but also translates to cost savings for the construction company.

The Importance of Proactive Maintenance

A proactive maintenance approach, where a company identifies and addresses potential problems before they escalate, can be a game changer. Scheduled maintenance, inspections, and proper training for workers are key components of this approach. Implementing a proactive maintenance routine helps avoid unexpected disruptions in work and enhances the project’s overall success.

Why equipment maintenance matters in construction cannot be overstated. Regular upkeep of construction equipment brings a wide range of benefits, from enhanced productivity and efficiency to reduced environmental impact. By integrating proactive practices and educating workers on the importance of maintenance, construction companies can complete projects more efficiently, maintain a safer work environment, and, ultimately, save time and money.